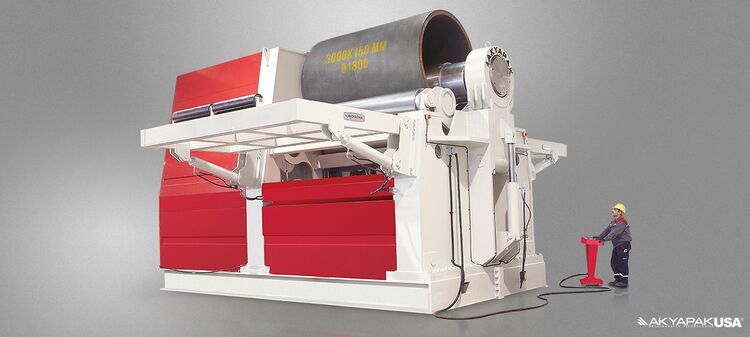

Akyapak AHS 30/16 CNC Plate Roll Capacity ¾” X 10’ Four-Roll, CNC, Hardened rolls, oil cooler, variable speed, prepared for top/side supports

Plate Rolls

Akyapak AHS 30/16 CNC Plate Roll CAPACITY ¾” X 10’ , CNC, Hardened rolls, oil cooler, variable speed, prepared for top/side supports

Akyapak has 54th years of experience and engineering expertise in a variety of products. Akyapak’s passion and dedication, which are reflected in every Akyapak machine in the market, to provide premium engineered solutions allow us to be more than your typical machinery manufacturer.

AK400 CS6 CNC Control, Variable Speed of Rotation, Prepared for Overhead and Side Supports, Oil Cooler, Induction Hardened Rolls, Two Speed Control.

Standard Equipment;

Cone bending device

Induction hardened rolls

Digital display for side rolls

Fully welded steel (St-52) construction body

Separate moving control panel

Two rolling speeds

Electro-hydraulic calibration

All rolls are mounted in roller spherical roller bearings

Safety equipment around the machine

Central rolls are driven by hydraulic motors and planetary gearboxes

Certified by CE, ISO9001 – 2008, TSEK and TURQUM

Optional Equipments;

Central and side supports

Variable speed of rotation

Material feeding table with various features

Interchangeable top roll

Oil cooling system

Driven side rolls

Automatic material ejection equipment

Automatic loading and unloading system

Deflection compensating system

Motors in variable voltage and frequency

| Length of Rolls | 10' |

| (Init/Dbl Pinch or Pyramid) | DBL PINCH |

| Max Thickness | 3.4" |

| # Rolls | 4 |

| Hyd/Mech | Hyd |

| Power | 20 hp |

| Roll Diameter | 16' |

| Control | CNC (AK400 CS6) |

| Dimensions | 18.4'L x 5.6'H x |

| Weight | 26250 lbs |

TECHNICAL SPECIFICATIONS – AHS 30/16

Working length Ft. 10’

Maximum thickness in

Pre-bending – 5/8”

Bending – 3/4”

Yield Point: 36,000 PSI

Number of rolls 4

Motor Power hp 20

Rollig speed up to ft/min 16

Min. diameter in - Ø Top Roll Diameter x 3

Top roll in - Ø 14.2”

Pinch roll in - Ø 13”

Side roll in - Ø 9.8”

Length ft 18.4’

Height ft 5.6’

Width ft 6.2’

Weight 26,650 lbs