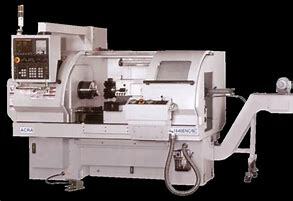

ACRA’s 1640 ENC CNC teach lathe with Fanuc OI Mate TD Controller

CNC Lathes

ACRA’s 1640 ENC CNC teach lathe with Fanuc OI Mate TD Controller

This lathe is a versatile teach type CNC flatbed lathes with Manual, Conversational, Teach, and CNC operating modes. The bed features a rugged MEEHANITE casting, with thick widely spaced cross supports and induction hardened ground ways for accuracy and rigidity. Coolant system with removable tank is standard. Precision ground ball screws are driven by AC digital servo motors. The spindle is driven by an infinitely variable AC Inverter and includes constant surface speed and threading functions.

The Spindle is driven through a 2-speed gearbox by an infinitely variable AC Inverter and includes constant surface speed and threading functions. This machine will be useful on day #1 with any level of operator, for production or prototype. It can be operated manually with jog joysticks and MPG hand wheels, Teach and Repeat, user interactive Conversational, or full-blown CNC G-Code / M-Function with macros. Some models include a Part Shape program generator, with graphics display

Standard Equipment:

• FANUC OI Mate – TD.

• Hydraulic Chuck 6″ with Rotary Cylinder.

• Coolant System.

• Hydraulic V8 Turret

• Hydraulic Tailstock

• Rotating Center MT.4.

• Level pads — 10pcs.

• Tool set & box.

• Work Light.

• Operation manual and parts list.

• The Electric H4 turret is driven by a worm gear/worm wheel mechanism for convenient tool change. It is powered by a 375 W. motor with great clamping force up to 1 ton.

• Specially designed post body prevents coolant and chips getting into post. Body will not move up and down during indexing.

• V8 Hydraulic Turret and Quick-Change Tool Post.

• The Spindle is supported by a single cylinder bearing housing equipped with SP level precision angular contact thrust bearings and lubricated with HI-class grease. The front spindle is designed with a labyrinthian collar and protector cover to prevent the entering of coolant or chips.

• Encased in a well-ribbed Headstock for maximum heat dissipation. Prevents any thermal distortion after long periods of turning thereby ensuring accurate cutting.

• Rigid construction and increased throat depth on Tailstock with MT#4 interior taper quill. When applying manual 4-way tool post, electric H4 turret or hydraulic P8 turret, it allows free cutting of long work pieces. When performing manual drilling, the quill can be set to zero for drill depth measurement. Can by optionally equipped with a Hydraulic Quill to automatically forward and reverse.

| Swing | 16.14" |

| Machining Length | 27.55" |

| # Axis | 2 |

| Chuck Size | 6" |

| Bar Capacity | 1.81" |

| Power | 7.5 hp |

| Max RPM | 5,000 RPM |

| Turning Dia | 8.66" |

| Tailstock | Yes |

| Live Tooling | No |

| Sub Spindle | No |

| Control | CNC (FANUC 0i Mate-TD) |

| Dimensions | 100" x 80" x 87" |

| Weight | 5,842 lbs. |

Specifications:

Workpiece Capacity:

Swing over Bed: 16.14″

Max Working Length (4 Way Tool Post): 27.55″

Max Working Diameter (4 Way Tool Post): 8.66″

Between Centers: 35.82″

Width of Bed: 10.236″

Spindle:

Spindle Nose: A2-5

Spindle Center Sleeve: MT #4

Spindle Bore / Bar Capacity: 1.81″

Number Range of Spindle Speeds: Inf. Vari. 40 – 5,000 RPM

Motor: 7.5 HP (10 HP Opt.)

Travel X: 8.07″

Travel Z: 34″

Rapid Travel: 393.7 IPM

Axis Motor: 1.0 HP

Z Axis Motor: 1.6 HP

Turret:

Tool Station: Standard Manual 4 Way Tool Post

Boring Bar Diameter: 0.787″

Tailstock:

Quill Taper: MT #4

Quill Diameter: 2.28″

Quill Travel: 5.5”