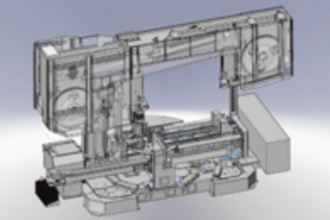

DAITO Model GTR5010CNC Double Miter Cutting Bandsaw

Horizontal Band Saws

DAITO Model GTR5010CNC Double Miter Cutting Bandsaw

Some might say that the phrase “state-of-the-art” was coined in anticipation of Daito’s new GTR5010CNC double miter cutting band saw machine. This machine is loaded with innovations and they all add up to speed and accuracy.

As larger beams are sawn, they often stress relieve and may wedge the blade in the cut on old fashioned machines but not on the Daito GTR5010CNC Because the machine knows the exact dimensions of the beam it is sawing, it anticipates where the blade might wedge and automatically “woodpeckers” through the cut so that it will not wedge the blade in the cut.

This machine is the fastest cutting band saw machine on the market with average cutting rates of 90 square cm/minute. The computer controls the entire cut. The machine automatically sets the blade speed, automatically sets the feed rate and automatically sets the feed pressure. No knobs to turn. No buttons to push. No operator guesses and no errors. The machine automatically sets all the right speeds and feeds for the material

being cut and even automatically adjusts the feeds and speeds during the cut as needed.

No more guessing at which pitch band saw blade pitch to use when you change material size with the GTR5010CNC. You always use a 3-4 pitch blade and the machine automatically optimizes all the settings for that pitch blade. Even miter cuts are automatically handled by the saw. There are many, many more features on this machine that make it truly a dream saw and it seamlessly integrated into this drilling/sawing cell to produce flawless results.

Chip conveyor

• Misting unit

• Motion detector

• Hydraulic vertical clamp

• Infinitely variable blade speed

• Band saw blade

• Hand tools, Operating, maintenance and parts manual.

Additional Standard Features for GTR5010CNC Bandsaw

• A hydraulic vertical clamping system dampens vibration when cutting larger sections and can be fixed to allow bundled cutting of smaller pieces.

• Naturally, positioning of the massive moveable guide arm is automatically adjusted so that you always have your guides as close to the material as possible for maximum beam strength. There is a hydraulic hold down that exerts pressure on the web to significantly reduce harmonic vibration when cutting the web. The hydraulic hold down not only contributes to remarkably quieter cuts but also increase blade life by minimizing the vibration to which the blade is subjected.

• The Rapid Approach Arm causes the saw blade to rapidly approach the material and then automatically slow to the cutting speed just prior to tooth penetration. This reduces total cycle time by minimizing time wasted “cutting air”. Additionally, this device automatically establishes the height of the material so that the saw blade will return to the proper position upon completion of the cut.

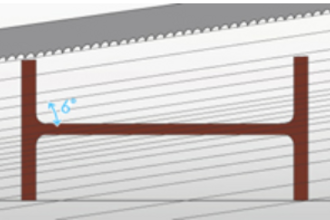

• A fixed 6 degree approach angle of the saw blade limits the area presented to the blade during cutting. This allows the use of finer pitched blades to minimize tooth stripping and to provide faster cuts with better finishes.

• Carbide guides, hydraulic power clamp front to back, backed up by Daito’s exclusive solid carbide roller assure accurate guidance, quieter cutting, less downtime and lower maintenance costs.

• The massive saw frame provides a stable platform to mount the blade. Tension and blade tracking are constant. Large diameter wheels limit stress on the blade to assure maximum life.

• Blade speed change is achieved via AC inverter.

• The hydraulic powered blade tension system provides error free blade tension to ensure accuracy and blade life.

• The machine is equipped with a spray mist type cutting fluid system that effectively lubricates the blade for extended cutting tool life but eliminates the problems and waste associated with cutting fluid running down the material and spilling onto the floor. This cutting fluid mist system is provided so that the problem of cutting fluid waste is eliminated providing lower cost per cut and a safer work environment.

• A motion detection which shuts the machine down in the unlikely event the blade should wedge in the material or if the blade should break.

• A Powered Chip Conveyor is provided to contribute to greater productivity.

| Rect-Cap (H) | 23.625" |

| Rect-Cap (W) | 23.625" |

| Rounds-Cap | 23.625" |

| Power | 10 hp |

| Type (Auto, Manual, Semi) | Semi |

| Blade Width | 2.125" |

| Blade Thickness | 0.0625" |

| Blade Length | 368" |

| Dimensions | 179" x 88"D x 1167" H |

| Weight | 17,650 lbs |

Technical Specifications for GTR5010CNC Bandsaw

Capacity at 90 Degrees:

• Square 23 5/8”

• Rectangular: 40” x 21 3⁄4”

Capacity at 45 Degrees:

• Square: 21 3⁄4”

• Rectangular: 21 3⁄4” x 21 3⁄4”

Capacity at 30 Degrees:

• Square: 11 13/16”

• Rectangular: 11 13/16” x 21 3⁄4”

Vice Capacity:

• Max: 41”

• Min: 2 9/16”

• Force: 2,315 lbs

• Speed: 13 ft/min

Blade Size: 368” x 2 1/8” x t 1/16”

Saw Wheel Diameter: 31 1⁄2”

Blade Drive: 7.5 Kw

Blade Speed (AC Inverter Control): 0 to 440 ft/min

Hydraulics:

• Hydraulic Pump Motor: 5.5 Kw

• Pump Output: 8 1⁄2 gallon /min.

• Nominal Operating Pressure: 155 lbs / psi

• Fluid Reservoir: 26 gallons

Coolant:

• Pump type: impeller

• Pump motor: 0.25 Kw

• Capacity: 16 gallons

Column Size: 7 7/8” x 15 3⁄4”

Overall Dimensions:

• Width: 179”

• Depth: 88”

• Height: 116”

• Table height: 32”

Net Weight: 17,650 lbs