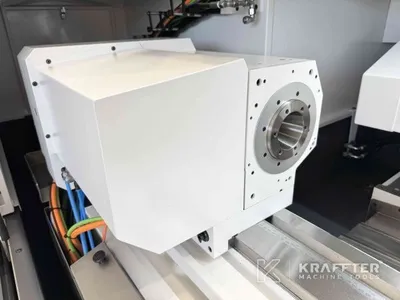

STUDER CNC ID/OD Cylindrical Grinder, Overhauled in 2025, Workpiece Spindle Speed 1,500 RPM

COMPLETE OVERHAUL IN 2025:

Complete dismantling of the machine

Hand scrapping of X and Z axes guideways

Regrinding of both X and Z tables

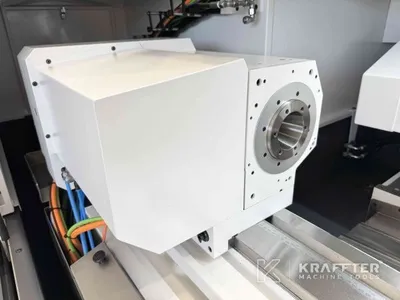

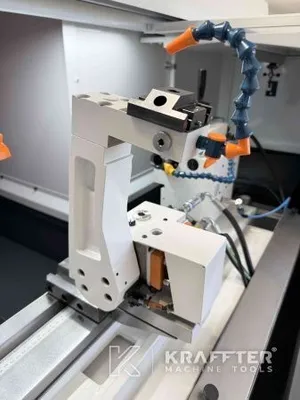

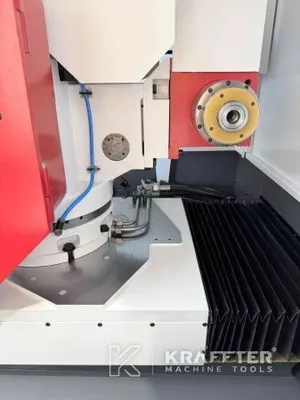

Complete rebuild of the B axis

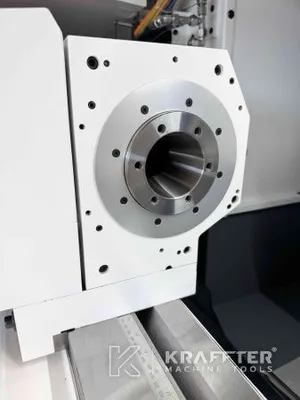

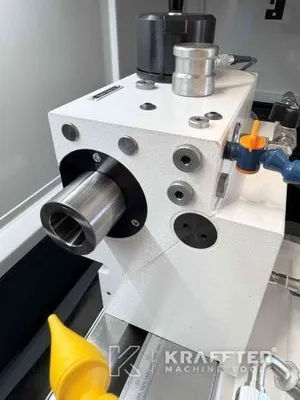

Complete rebuild of the workpiece spindle

Geometry of the headstock and tailstock done according to the STUDER protocol

Geometry of the Z axis done accordingly to the STUDER protocol

Geometry of the X axis done accordingly to the STUDER protocol

Complete refurbishment of both X and Z axes ball screws: complete cleaning, replacement of each set of balls with balls of the correct diameter and

new set up of the nut/screw preload

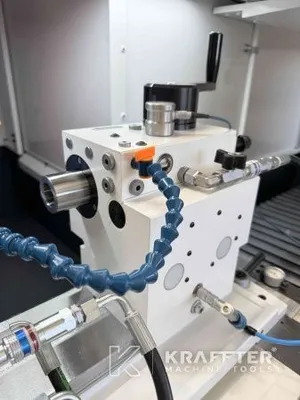

Vibration level analysis of external grinding spindle

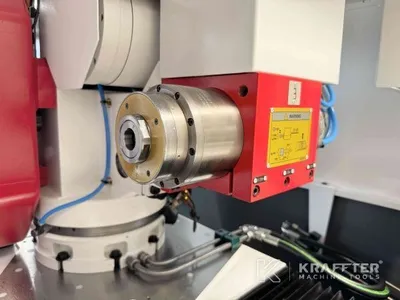

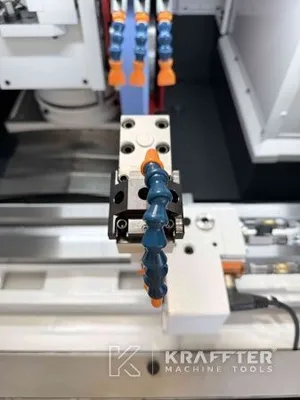

Vibration level analysis of internal grinding electro-spindle

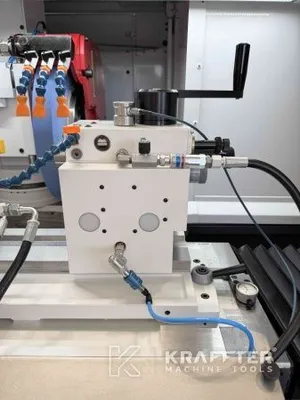

NEW pneumatic hoses

NEW hydraulic hoses

NEW hydraulic oil filters

NEW grinding spindle belt

NEW workhead spindle belt

NEW MOVOMATC C25 part probe

NEW air filters for the ABSOLENT mist extractor

NEW FANUC drive batteries

NEW bellows on Z and X axes

Replacement of all bearings of the machine

Replacement of all the gaskets, shaftseals and O-rings

Complete painting of the machine and equipment (in polyurethane 2K paint)

STUDER – Swiss Precision in Cylindrical Grinding:

Founded in 1912 and based in Steffisburg, Switzerland, STUDER is a flagship brand of the UNITED GRINDING Group, one of the world's leading manufacturers of high-precision grinding machines. With over 25,000 machines delivered worldwide, STUDER specializes in universal, internal, external, and non-cylindrical grinding machines designed to meet the highest industrial standards.

Renowned for its engineering expertise, Swiss precision and continuous innovation, STUDER serves demanding sectors such as aerospace, medical, automotive, precision mechanics, and tooling. Its machines combine advanced CNC technology, intelligent automation, and proven reliability, making Fritz Studer AG a benchmark in precision grinding.

📽️ Presentation of the STUDER S33:

The STUDER S 33 is a universal CNC cylindrical grinder designed to offer exceptional application versatility. It performs both internal and external grinding on a wide range of cylindrical workpieces with high precision.

Equipped with a B-axis and an intuitive FANUC 21i-TB control, it ensures consistent, accurate, and repeatable results.

The S33 is ideally suited for industries where surface quality, tight tolerances, and process reliability are critical, such as aerospace, medical, and high-precision engineering.

UNITED GRINDING Group – A Global Leader in Grinding Technologies

The UNITED GRINDING Group is one of the world’s leading manufacturers of grinding, erosion, laser, and measuring machines, as well as machine tools for additive manufacturing. With more than 2,300 employees across over 20 production, sales, and service locations worldwide, the group operates with a customer-oriented, efficient, and responsive organization.

Comprising internationally renowned brands such as STUDER, WALTER, EWAG, MÄGERLE, BLOHM, JUNG, SCHAUDT, MIKROSA, and IRPD, the group offers extensive application expertise, a comprehensive technology portfolio, and a full range of services for the production of high-precision components.

With over 150,000 machines delivered worldwide throughout its century-long history, UNITED GRINDING is recognized as a reliable partner for complex machining tasks, both for single parts and series production.

EQUIPMENT INCLUDED:

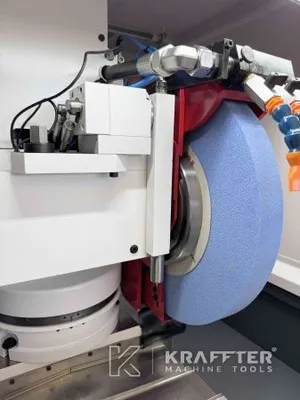

x1 internal grinding electrospindle FISCHER type MFM-1224/42 HJND-21 - speed: 42000 [rpm]

x1 cooling unit for internal grinding spindle

x1 automatic B axis - Hirth 1 [°]

x1 MOVOMATIC C25 part probe

x1 DITTEL SENSITRON 2 acoustic monitoring system

x1 ARO TECHNOLOGIES AG paper tape filtration device

x1 ABSOLENT AB oil mist extraction unit type ODF 1000c

x1 electric cabinet air conditioner

x1 set of user manuals (English, French and German)

TECHNICAL CHARACTERISTICS:

Year of manufacturing : 2006

Year of rebuild : 2025

CNC control : FANUC 21i-TB

Centre distance : 1000 [mm]

Height of centers : 175 [mm]

Stroke X axis : 285 [mm]

Min. Stroke speed X axis : 0.001 [mm/min]

Max. Stroke speed X axis : 5000 [mm/min]

Resolution X axis : 0.0001 [mm]

Stroke Z axis : 1150 [mm]

Min. Stroke speed Z axis : 0.001 [mm/min]

Max. Stroke speed Z axis : 10000 [mm/min]

Resolution Z axis : 0.0001 [mm]

B axis swivelling stroke : -15 [°] / +195 [°] [°]

B axis indexing precision : Hirth 1 [°]

Automatic B axis : Yes

Workpiece spindle nose : ISO 50

Workpiece spindle max. speed : 1500 [rpm]

Type of attachment tailstock : MT3

Tailstock quill stroke : 35 [mm]

Tailstock quill diameter : 50 [mm]

Tailstock fine adjustment : +/- 40 [µm]

We use cookies to improve your experience. Privacy Policy.