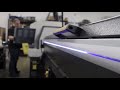

KSI Swiss 7-Axis Automatic Sliding Headstock CNC lathe Model TCM 20S Main Bore Dia 30mm; Sub-Spindle Bore Dia 20mm

$159,000

Description

KSI Swiss 7-Axis Automatic Sliding Headstock CNC lathe Model TCM 20S Main Bore Dia 30mm; Sub-Spindle Bore Dia 20mm

Our CNC Swiss machines are well known for giving you more without paying more. We understand the importance of these machines and want to provide our customers with the tools they need to create their parts or products. The KSI Swiss CNC machine is designed to work hard so you don’t have to. You can turn out more products and parts in less time than you can with other similar types of machines. This is why Swiss machines are the only types of machines we offer at KSI Swiss.

LED Red/Yellow/Green Signal Light

Parts Chute

Parts Conveyor

Sub Spindle Work Ejector

Cutting Oil Tank and Chip Pan are removeable and independent

200L Cutting Oil Tank

Main coolant pump flow sensor Sub-coolant (optional) Automatic Power-Off

Work-dual zone LED Lighting

Cut off tool breakage detector S/W M86

Tool life management system

Collision System prevention

Sub spindle Air Blow (thru sub- spindle long shaft ejection ready) Pre-Wired for Main Coolant, Pre-Wired for Sub Coolant

Pre-Wired for Chip Conveyor, Pre-Wired Flow Sensor

(4) M codes for High Pressure Coolant system

(2) M codes for application usage

M108 and M109 for additional secondary coolant pump

KSI Barload BWG21 Bar Feeder (20MM)

MP High Pressure Coolant System 2,000 psi, 5 gpm, 4 ports system $9,900.00

Installation goal, two days including travel time, remaining for training, travel expenses included (extra time available at additional charges)…$5,000.00

Machine Specifications:

Max Spindle Speed……………………………10,000 RPM Main Spindle Positioning C Axis……………… .001 Degrees

Sub Max Sub Speed…………………………………8,000 RPM Sub Spindle Positioning C Axis………………… .001 Degrees

Z1-Axis Stroke………………………………………… 300mm Z2-Axis Stroke………………………………………… 300mm X1-Axis Stroke………………………………………… 62mm

(OD: 6 ea., Cross Live: 4 ea., ID: Fixed 5 ea., Ecc: Fix 1 ea. - live 2ea.) Ball-screw Diameter………………………………… 25 mm

Capacity Specs:

Main Spindle……………………………………………Drill/Tap 10mm/M8 (ER16) Cross Spindle……………………………………………Drill/Tap 8mm/M6 (ER16) Back working……………………………………………Drill/Tap 10mm/M8 (ER16) Main Spindle Turning Tools………………………6 Standard (Fixed)

Y Axis Tool Block………………………………5 Standard (Fixed) Headstock Collet Size……………………………TF25

Face Tools (Sub Spindle T23) 1 Standard (Fixed) Face Tools (Sub Spindle T21,22)……………… 2 Standard (Live)

Live Face Tools (Back End) 2 Standard (Live) T32,31 optional Fixed Face Tools (Back End) 2 Standard (Fixed) T33,34 optional Total No. of Fixed Tools……………………………13 Standard

Total No. of Live Tools……………………9 Standard Total No. of Tools…………………………………… 26 Standard Driven Rotary Guide Bushing……………………Standard

Motor Specs:

Main Spindle Motor…………………………………3.7Kw (5HP) Sub Spindle Motor……………………………………2.2Kw (3HP) Cross Drill/Mill Motor………………………………1 Kw

(All axis machine motors are High Torque) Rigid Tap (All Mill/Drill)

CNC Control Fanuc Oi-TF:

10.4” Color CRT Monitor

Dual Path Control

Simultaneously Controlled 6-axis Manual Pulse Generator MPG Handle incremental feed

Manual handle trace

Thread cutting/synchronous cutting G92

Multi-lead threading G76

Continuous threading G32

Spindle orientation, and Spindle synchronous control (Main & Sub) Smart rigid tapping

Spindle speed fluctuation detection G25

Maintenance information screen

Trouble diagnosis

Embedded ethernet, USB Interface, RS-232, Type CF memory Card

G70 - G76 canned cycles

G7.1 Cylindrical Interpolation

Helical Interpolation for thread milling, 3 Axes simultaneous machining including 2 linear axes and 1 rotary axis

G12.1 Polar Coordinate Interpolation

Variable thread cutting Rigid tap all spindles Polygon Turning G51

Custom macro common variables between each path

Canned Cycles G80 - 88

Specifications

| Manufacturer | KSI |

| Model | TCM 20S |

| Year | 2021 |

| Condition | New |

| Stock Number | 21528 |

| Status | For Sale |

| Spindle Hole Dia | 0.78"; 19.812 mm |

| Power | 5 hp; 3.7 kW |

| RPM | 10,000 RPM; 10,000 RPM |

| # Axis | 7; 7 |

| Control | CNC (FANUC 0-TF); CNC (FANUC 0-TF) |

| Dimensions | 107" x 59" x 46"; 107" x 59" x 46" |

| Weight | 8,050 lbs; 8,050 lbs |

| Hydrodynamic Magazine Barfeed System, Guide Channel Set | $19,900.00 |

| MP High Pressure Coolant System 2,000 psi, 5 gpm, 8 port sys | $10,900.00 |

| Timist, Model 850G mist collector used, machine mounted | $3,300.00 |

| LNS Hinge Belt Standard Chip | $9,900.00 |

| LNS Turbo Dual Belt Scrapper System with 250 Micron Filtration | $11,900.00 |

| Fire trace 6lb Fire suppression system with install | $5,500.00 |

| Fire trace 12lb Fire suppression system with install | $7,000.00 |

| Main Spindle Bore Diameter | 30mm (1.181") |

| Main Spindle Horsepower | 5HP |

| Sub Spindle Bore Diameter | 20mm (.787") |

| Sub Spindle Horsepower | 3HP |

| Maximum Turning diameter | 20mm (.787") |

| Y-Axis Stroke | 391.5mm |

| X2-Axis Stroke | 405mm |

| Number of tool stations | 27 Total |

| Main side | 18 Total |

| Ballscrew Lead | 10mm with S/W limit, and mechanical stop |

| Slide ways are LM guide design | Rexroth Bosch |

| Tool Shank Size | 16mm (5/8") |

| Main Spindle Cross Live Tools | 4 Standard (Live) |

| Guide Bushing Size | TD25 |

| Sub Spindle Collet Size | TF25 |

| Cross/Back End Working Spindle Speed | 5,000 RPM |

| Back End Motor | 1 Kw |