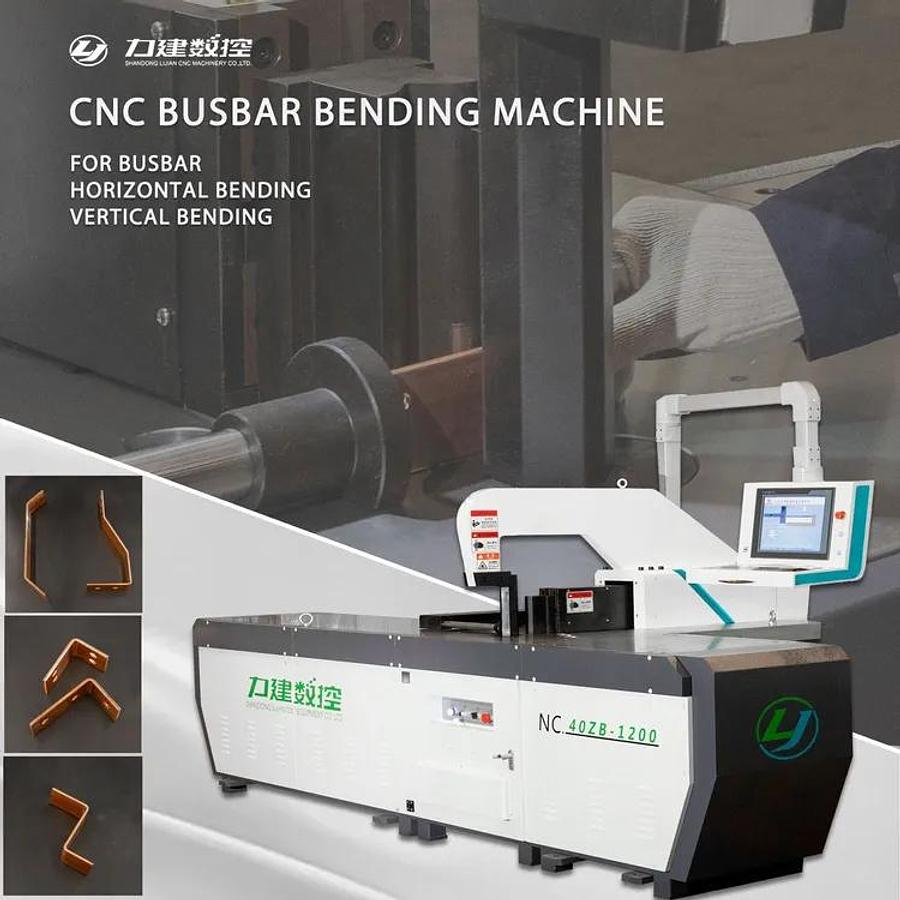

LIJIAN MODEL NC 40ZB 1200 CNC Busbar Bender, Servo Powered by Rexroth, 40 Tons, 10HP Motor

Description

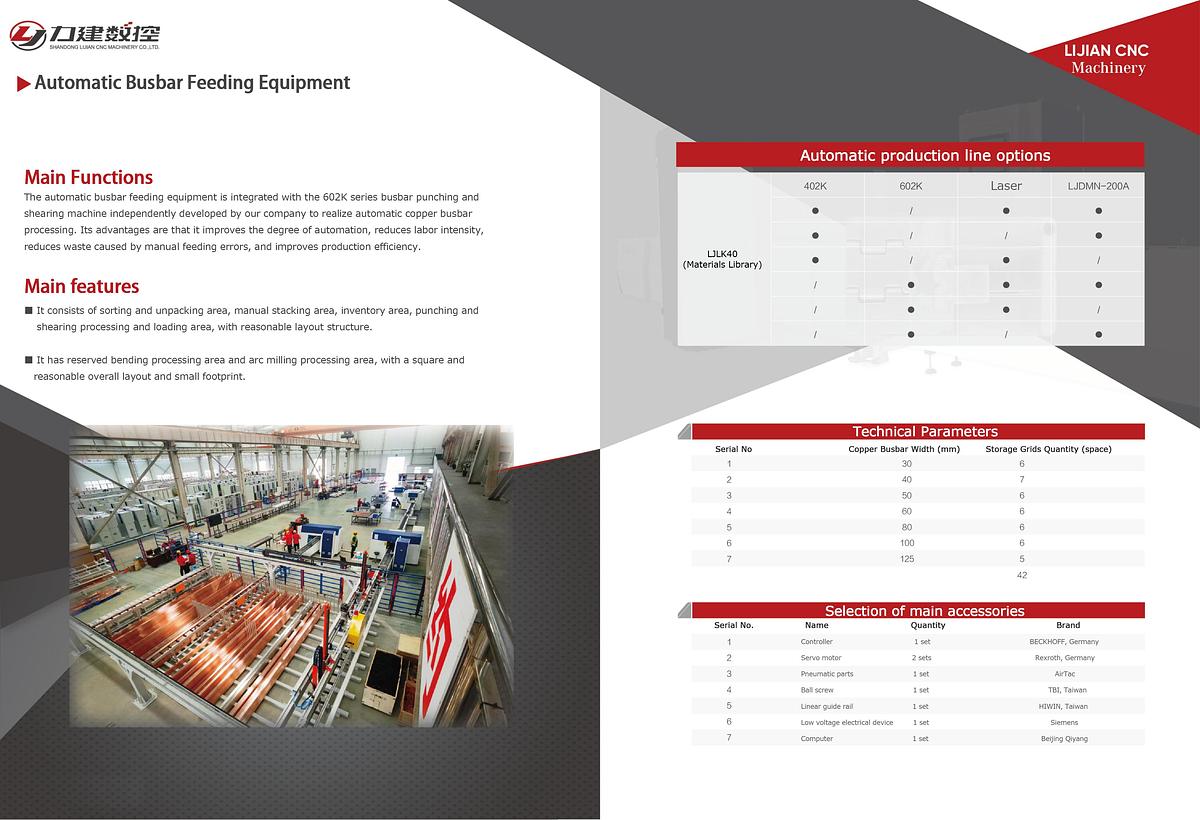

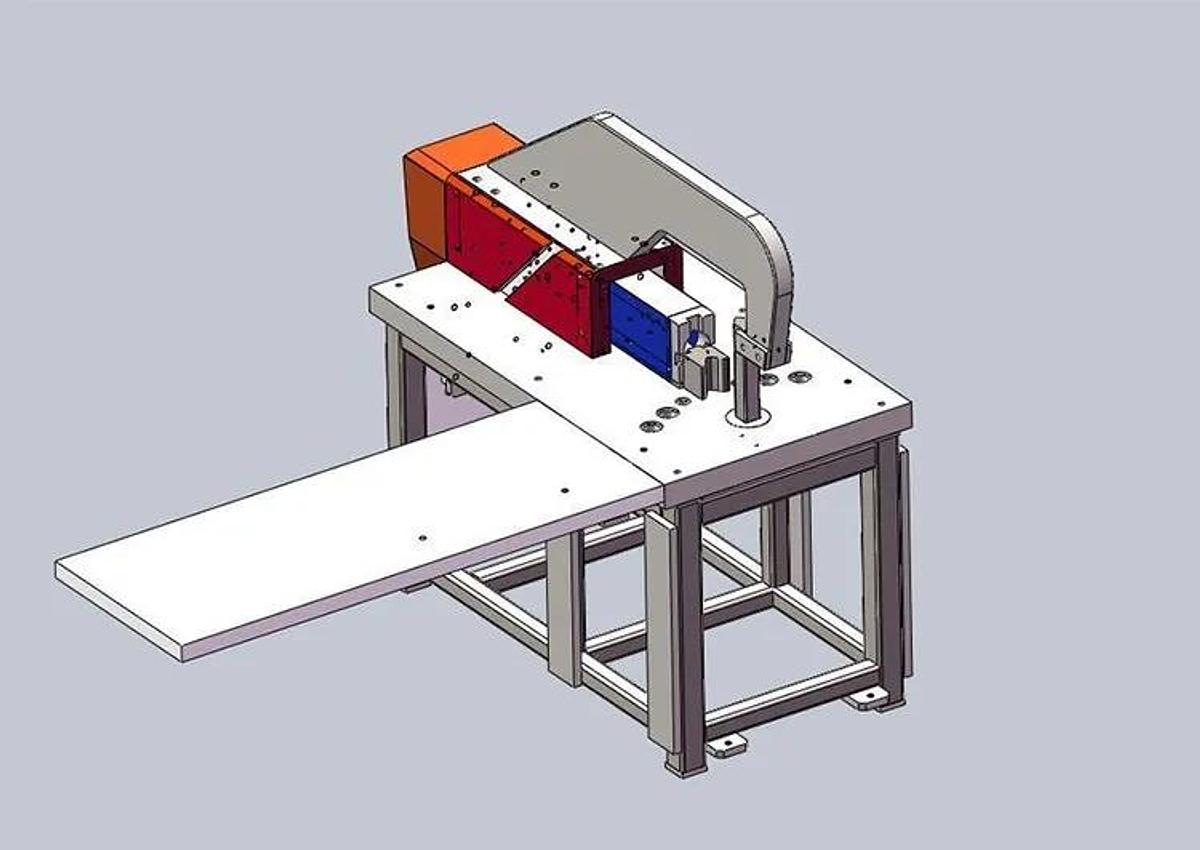

LIJIAN MODEL NC 40ZB 1200 CNC Busbar Bender, Servo Powered by Rexroth, 40 Tons, 10HP Motor The CNC Busbar Bending Machine is a precision-engineered solution designed to automate the bending process of copper and aluminum busbars with high accuracy and repeatability. Equipped with advanced CNC controls, this machine enables operators to program complex bending angles and shapes, significantly reducing manual errors and production time. It is widely used in power distribution systems, electrical panel manufacturing, and switchgear production. The robust hydraulic system and user-friendly interface make it ideal for high-volume busbar fabrication, ensuring consistent quality, improved efficiency, and minimized material waste. Shandong Lijian CNC Machinery Co., Ltd. Jinan Lijian CNC Machinery CO., LTD. is professional high technology enterprise engaged in the development and the manufacture of electrical engineering equipments and sheet metal processing equipments, the company is located spring city Jinan, the products are high performance based on the powerful technology research and development capacity and product's prices are very economic . We provides various Busbar Processing machines with punching, bending , cutting function and Busbar Punching-shearing Machines, CNC Metal Sheet front-feeding Shearing machines, CNC Sheet Metal Press Brake Shearing machines, CNC hydraulic Turret-type punching machines, CNC Busbar Bender and Busbar leveler machines. the operation is very convenient, the machines are very durable. There is video of the work operation for the machines on our website, The machines have passed several quality management system authentications. The series Busbar machines are widely used for processing (aluminum and copper) busbars in electric industry, including high/low voltage electric apparatus, the transformer, Busbar duct, communication equipments, office automation, the manufacture of the electric elevator, air conditioner manufacture, Sheet metal processing, etc . Our products were praised by the customers. I. Introduction: The NC.40ZB-2000 CNC busbar bending machine is an efficient, highly automated, and high-precision equipment used for bending copper and aluminum busbars. The machine is powered by servo motors, controlled by CNC units, and equipped with a self-developed CAD/CAM software system. This ensures that the machine's level of automation is at the forefront of the industry. It is an ideal equipment for busbar processing in industries such as complete sets of high and low voltage equipment, box-type substations, transformers, and busbar slots. The machine adopts large inertia servo motor as the main power to provide transmission power for high-precision planetary reducer and grinding ball screw. Compared with the traditional hydraulic bending machine, it has the following advantages: 1.The transmission is stable, the repeated positioning precision is high, the precision is not influenced by the temperature, and the stability is higher. 2.Automatic stop function is available in standby mode, which greatly reduces working energy consumption. 3.The machine adopts servo motor as power, solving the trouble of oil leakage caused by hydraulic transmission. 4.When working, the sound of the servo motor is low, reducing the noise pollution. 5.It has the centering capacity carrying mode, and the linear guide, which balance the stress, and reduce the influence of eccentric load and friction on the service life and processing precision of the lead screw. 6.The material stopping ruler is divided into three gears, which can be adjusted manually according to the processing technology, thereby greatly improving the working efficiency. Selection of main components: 1 Servo motor Rexroth 1 pc. 2 Spindle lead screw Nanjing Technological Equipment 1 pc. 3 Precision planetary speed reducer TECHMECH 1 pc. 4 Linear guide HIWIN/PEK 5 pcs 5 AC contactor Siemens, Germany 1 pc. 6 Computer Beijing Qiyang 1 pc. 7 Positioning lead screw TBI, Taiwan 1 pc. 8 Industrial switch TP-LINK 1 pc. 9 Programmable controller Beckhoff, Germany 1 pc. Parameter comparison: 1 Nominal pressure KN 400 2 Spindle motor power KW 7.5 3 Bending accuracy ° ±0.3 4 Spindle stroke mm 200 5 Material blocking accuracy mm ±0.15 6 Maximum size of flat bending mm 15×200 7 Maximum size of vertical bending mm 12×120 8 Material blocking length mm 2000 9 Machine weight KG 3300 10 Appearance and size mm 4300×1450×1850

Specifications

| Manufacturer | LIJIAN CNC Machinery |

| Model | NC-40ZB-1200 CNC Busbar Bender |

| Year | 2025 |

| Condition | New |

| Stock Number | 22233 |

| Status | For Sale |