MECO MEC ARC 150 x 1150 x 1175 Keyseater/Slotting; 45.28H" and 2.0" to 10.24" keyway width. Four interpolated Axes: X, Y, Z, & W.

Description

MECO MEC ARC 150 x 1150 x 1175 Keyseater/Slotting; 45.28H" and 2.0" to 10.24" keyway width. Four interpolated Axes: X, Y, Z, & W.

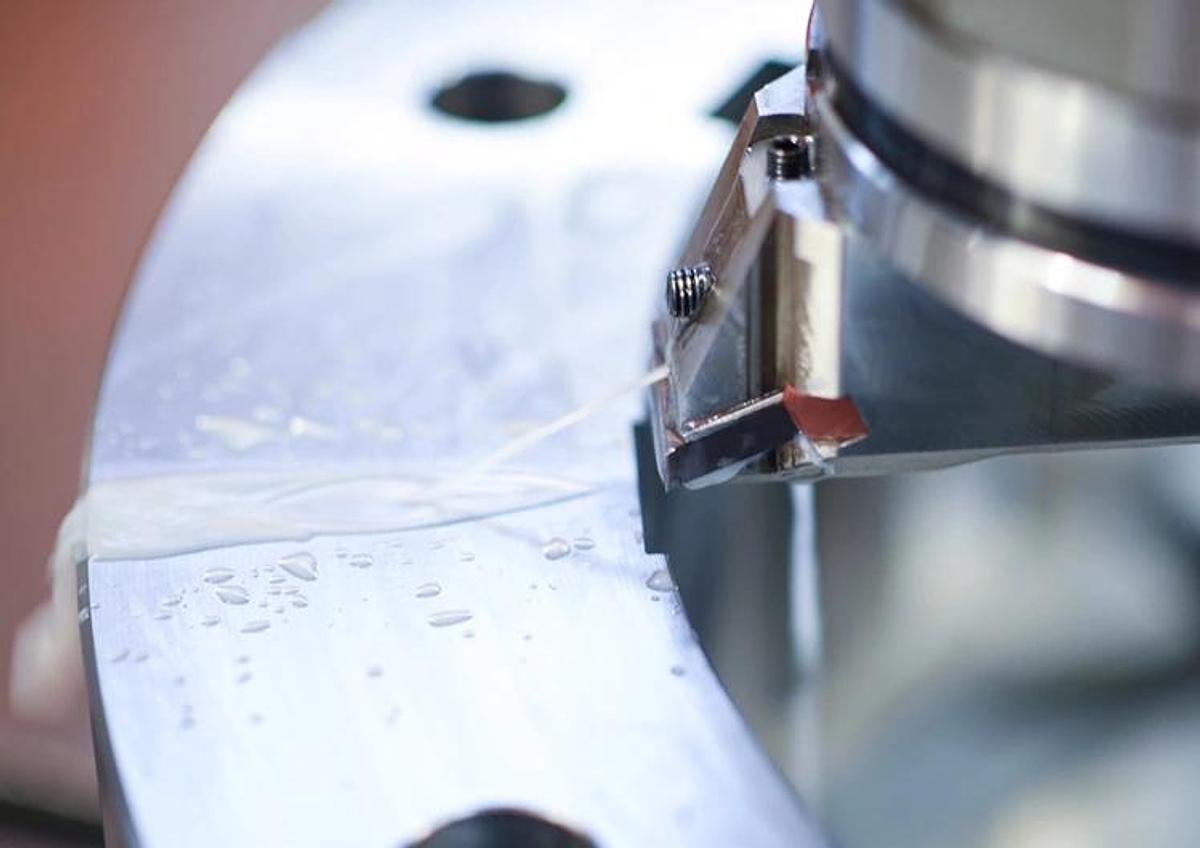

The first ideal bridge notching machine for giant workpieces MEC ARC is a new conception of notching: it is the result of years of experience in the construction of this type of machine. MEC ARC is initially conceived to deal with the machining of large dimensions with notches and grooves of any geometry and size, both inside and outside of them.

The arc configuration of the MEC ARC range provides unprecedented working rigidity in this type of machining. MEC ARC has four work axes synchronized with each other thanks to the implementation of a CNC system. The incorporation of CAM in the system allows the MEC ARC to work without any limitations when defining any type of geometry, no matter how complex it may be, and always with maximum precision.

With the MEC ARC range, MECO reaches its maximum exponent in terms of technological capacity, designing and custom-building the MEC ARC most suitable to the needs of each client. MEC ARC is a unique and revolutionary notching machine that, without a doubt, places us at the forefront in the construction of this type of machines worldwide .

Ability to do blind parts

3 sets of ball screws

Chip collection by worm drive auger

PN Type toolholder that allows entire spindle to enter the part

Touch screen

Table has 6 radial T-slots

Spindle alignment system

Spindle of 6" diameter for toolholders

Cutter centering using two cutters edges to center the cutter

Straight slots, Helical Slots, Hexagonal, External Splines, Conical Keyways, Keyways in Blind Samples, Squares, Internal Splines an Blind Holes

High Load Working System lets 5-80mm width cutter can cut up to 350 slot

Capability:

STRAIGHT SLOTS

CONICAL KEYWAYS

HELICAL SLOTS

KEYWAYS WITH BLIND HOLES

SPECIAL KEYWAYS

SQUARES

HEXAGONAL

EXTERNAL SPLINES

INTERNAL SPLINES AND BLIND HOLES

Max. Diameter of Part 43.2"

Total Working Area (Z Stroke) 45.28

Max. Speed Z Axis 20m/min.

Max. Speed Y Axis 4m/min.

Total Y Axis Stroke 57.09"

Max. Rotation Speed ( W Axis) 3.2 RPM

Total Degree Rotation 360 degrees

Max. Diameter of Rotary Plate 42.32"

MEC-ARC 150X1150X1075 Premium CNC General

dimensions (length, width, height). 157"L x 98.43W x 157"H

Machine weight (Aprox).

Machine Type Bridge with unique arc

Cementing and implantation. No

Table dimensions. Ø47.24" Diameter

Maximum diameter over the table. (W Axis). Ø42.32"

Type of clamping system for the tools: Combined depending on the hole Ø of the piece

Clamping for SV tool-holders (holes form Ø2" to Ø10.23"). Morse cone type

Clamping for PN tool-holder (holes from Ø9.84"to 42.32", and for external slots):Screws and ring system

Extension system for the spindle. Optional

Refrigerant system:

Yes (15Lts/min)

Refrigerant recommended. WD-40

Maximum viscosity of work. From 5 to 10cS at 40ºC (1)

Oil filter system. Yes

Machine light Yes (800 Lumens)

Profitable stroke in “X Axis”. 17.72"

CNC model integrated in the machine: SIEMENS or MITSUBISHI (customer's choice, but price is different depending on choice)

The parameters below are for SIEMENS

Interpolation tolerance at F10000mm/min 0.05mm:

Specifications

| Manufacturer | MECO |

| Model | MEC ARC 150 x 1150 x 1075 Vertical Slotter/Keyseater |

| Year | 2024 |

| Condition | New |

| Stock Number | 21960 |

| Status | For Sale |

| Country | United States |

| Keyway Width | 10.24"; 260.1 mm |

| Keyway Length | 45.28"; 1,150.1 mm |

| Control | CNC (Mitsubishi); CNC (Mitsubishi) |

| Dimensions | 157"L x 98.43W x 157"H; 157"L x 98.43W x 157"H |

| Weight | 16,500 lbs.; 16,500 lbs. |

| 3 Automatic Axes | Z=45.28"; Y=57.09"; W=3.2 RPM of 42.32" rotary plate |

| Distance from the table to the bridge | 47.24" |

| Low level indicator for refrigerant liquid | Yes |

| Maximum pressure | 5 Bar |

| Programmable through M Code in the CNC | No |

| Flow regulation | Manual |

| Filtration degree | 0.2mm |

| Machine floor with oil collection tray | Yes |

| Collection chips system | Yes |

| Actuated from the CNC | Yes |

| Internal lubricate system for mechanical components | Yes |

| Lubrication system | Multipoint injection |

| Kind of oil for lubricate system | SAE-15 or equivalent |

| Maximum translation speed (G0) | 20m/min |

| Servomotor power | 6.02HP |

| Maximum force | 2800Kgf |

| Positioning accuracy | +- 3,5 arcsec |

| Positioning repeatability | 0.03mm |

| Profitable stroke in “Y axis” | 57.09" |

| Profitable stroke in “Z Axis” | 45.28" |

| Profitable stroke in “W Axis” | 360 degrees. |

| Maximum angular speed (G0) | 3.2 RPM/min |

| Maximum torque allowed for machining | 18 kN/m |

| Tangential torque with locked table | 40 kN/m |

| Maximum weight over the table | 22,000 lbs |

| Interpolation tolerance at F4500mm/min | 0.02mm |

| LAN network connectivity | Yes |

| Program management from SD card | Yes |

| Program management from PC | Yes |

| Maximum storage capability in the CNC | 64000 steps |

| Monitoring and display the individual axis power consumption | No |

| Effective torque limitation on each axis by the user | No |

| Maximum working speed (G1) | 15000mm/min |

| Speed in security mode with doors opened | 150mm/min |

| Web-CAM area visualization to local network (not CNC associated) | Optional |