Description

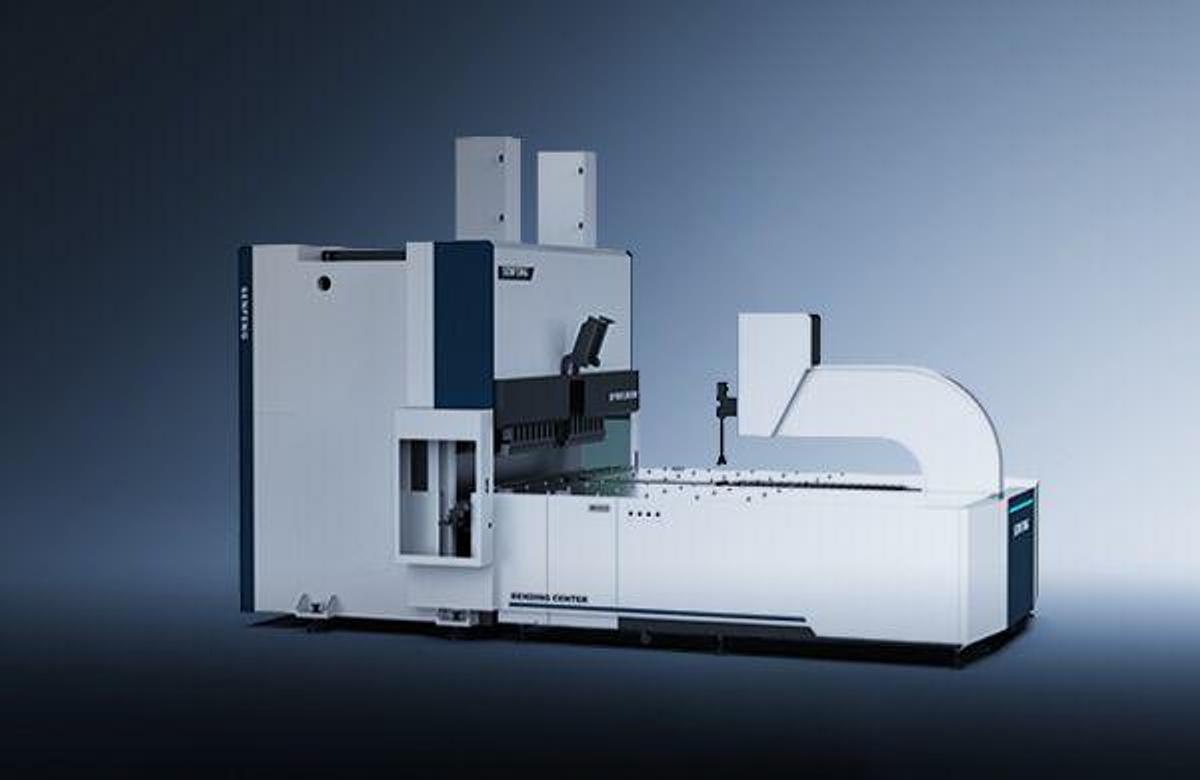

The new panel bender employs multi-axis concurrent linkage and universal bending tools to bend thin metal sheets automatically. It also features automatic tool changer to further enhance its level of automation and reduce reliance on molds and workers, so as to improve bending efficiency and lower production costs.

2500 [mm] Max bending length 1250 [mm] Max bending width 200 [mm] Max bending height 0.2 [S/bend] Max bending speed

Competitive Strengths

Performance Benefits

This highly integrated machine adopts press-down arm and universal bending tools to perform batch bending of large sheets in complex shapes. With less manual intervention, bending precision and quality are guaranteed.

1. Multiply bending speed

3 times faster than other CNC press brakes, namely, 0.2S/bend

2. Bend into various shapes

Bend upward & downward, enable arc, dead-edge, U-shaped, enclosed-type bending, bend in right, acute and obtuse angle, as well as other complex shapes

3. High consistency among workpieces

The reason why our bending consistency is high is that workpieces can be accurately positioned and under uniform stress

4. High level of safety

No hand holding is required for feeding, positioning and bending, minimizing potential safety hazards caused by misoperation

5. High degree of intelligence

High configurations in both software and hardware, with various functions for easy bending

Mechanical Benefits

1. Unique design

* Its machine tool bed is designed as triangular and of which some key components are made of 80mm steel plates in order to keep itself stable even under high-tonnage impact

* Its press-down arm uses upper and lower grippers to clamp workpieces even when there are pores, dents or they are in complex shapes. In a word, such feeding mode has low demanding on the quality of sheet surface

* Its universal bending tools are made of high-strength alloy/die steel and have got through dozens of procedures including solid forging, tempering and quenching in order to bend for millions of times.

2. Automatic tool changer

It can choose upper press tools in right amount according to sheet size, then, splice them into different lengths to bend sheets of different sizes. The tool changer will take the place of manual work and raise bending efficiency.

3. High-standard machine tool

Keep machine tool indeformable and unbroken at high temperature even after long-time use because of going through 7 standard processes like high annealing and aging treatment

4. Other auxiliary devices

Work with auxiliary knife to cope with other demanding tasks, make itself more flexible and enlarge its work scope

Control System Benefits

SENFENG intelligent CNC system, with multi-axis concurrent linkage and based on EtherCAT bus protocol, makes bending more flexible.

1. 64-axis concurrent linkage

Perform more complex bending actions such as bend workpieces of different sizes

2. Visual graphical programming

Only need to input bending data, then, bending instructions will be generated, with lower demands on workers

3. Self-diagnosis

Reduce maintenance costs, prevent unexpected shutdown and make it more reliable

Optional Benefits

1. Intelligent interconnection

Reserve robot/truss expansion interface for loading & unloading, so as to make bending, loading & unloading fully automatic.

2. Increase bending height

Generally, this panel bender comes standard with 200mm bending height (or 175mm when hinge cutter is used), but users may apply for 300mm (or 275mm under conditions above) based on their actual requirements.

Specifications

| Manufacturer | Senfeng |

| Model | BDC2500 |

| Condition | New |

| Max Bending Speed (S/bend) | 0.2 |

| Max Bending Length (mm) | 2500 |

| Bending Height (mm) | 200 (or 175 when hinge cutter is used) |

| Max Bending Thickness (mm) | 304 stainless steel: 1.5cold plate: 2.0AL sheet: 2.5 |

| Min Bending Thickness (mm) | 0.35 |

| Max Bending Size (L*W, mm) | 2500*1250 |

| Number of Axes | 23-axis concurrent linkage |

| Overall Dimensions (L*W*H, mm) | 5700*5200*3050 |

| Gross Mass (T) | 20 |