Description

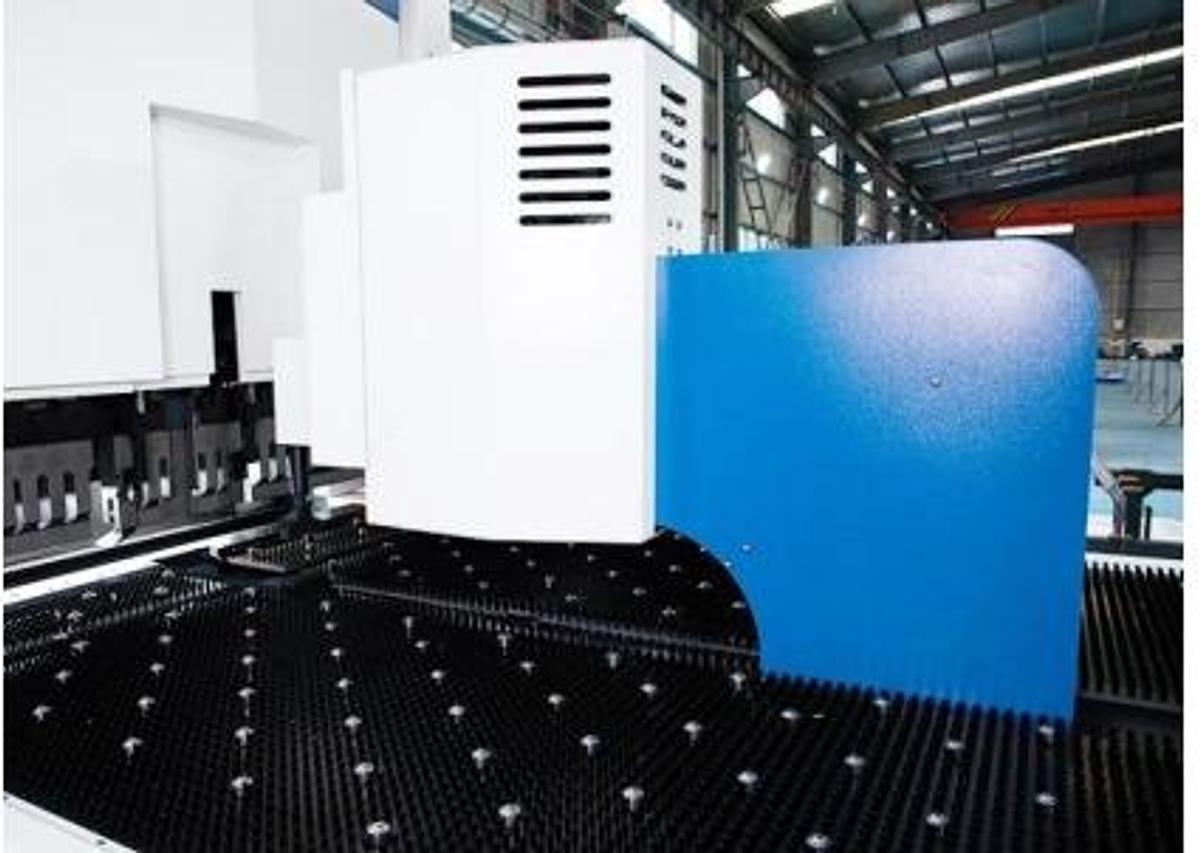

ADH Model PB-A Automatic Tool Exchange Panel Bender

SPECIFICATIONS I t e m

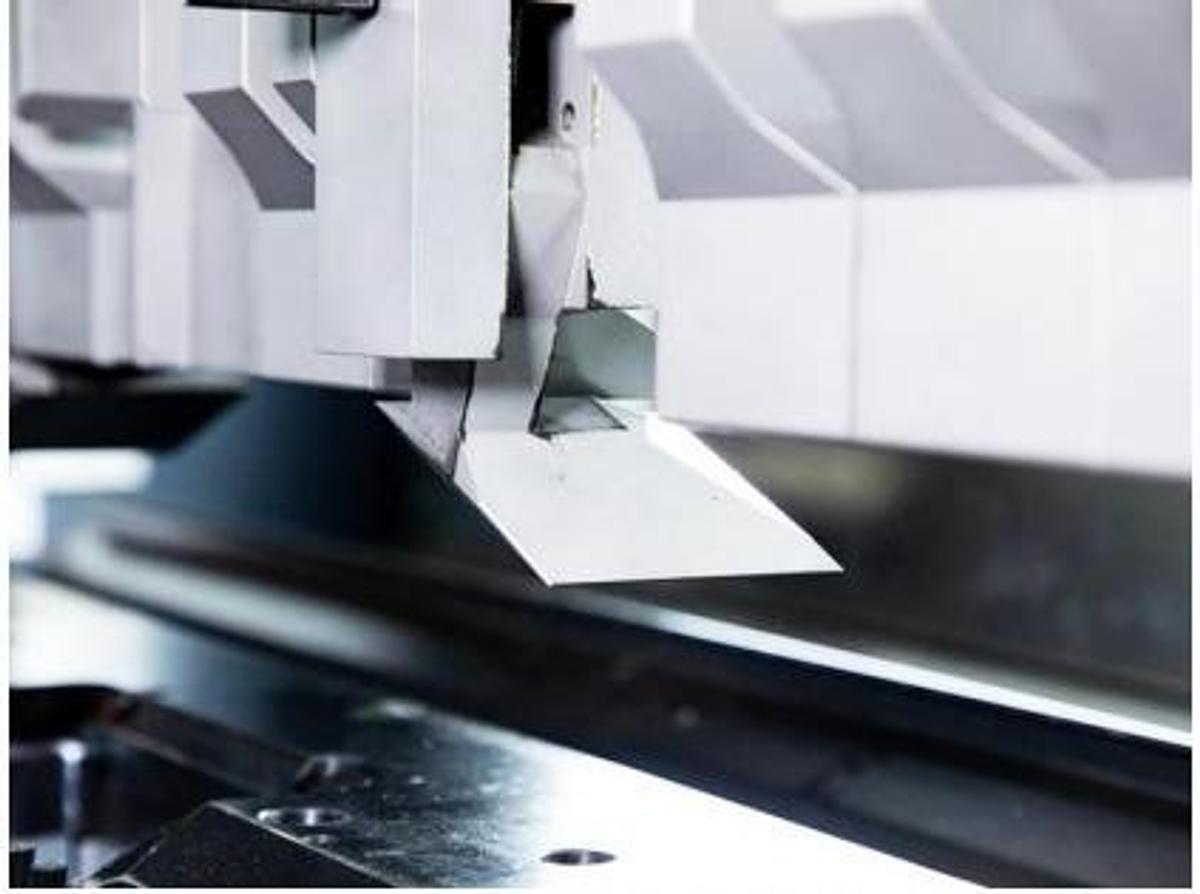

Bending Length 2610mm

Bending Height 200mm

Minimum Dimension for Four-Sided Forming 370/180mm

Minimum Dimension for Two-Sided Forming 180mm

Minimum Bending Height 6mm

Minimum Arc Radius 4mm

Maximum Diagonal 3040mm

Bending Angle /

Bending Speed 0.2s/bending

Number of Axes 22

Bending Plate Thickness

Cold Plate: 2mm

Stainless Steel: 1.5mm

Aluminum: 3.5mm

GalvanizedPlate: 2mm

Hot-Rolled Plate: 2m

Spindle Travel X-Axis: 150mm

Z-Axis: 230mmU-Axis: 1500mm

Y-Axis: 300mm

Feeding Structure pressingarm

Maximum Feed Speed 0.8m/minTool

Change Mode automatic

Upper Tool Pressure on Two Axis /

Worktable Structure Brush andball transfer

Total Power 118kw

Peak Power 76kw

Dimensions (L*W*H) 6200mm×4100mm×3350mm

TotalWeight 24tons

Specifications

| Manufacturer | ADH |

| Model | PB-A2610 Panel Bender |

| Year | 2025 |

| Condition | New |

| Stock Number | 22309 |

| Throat Depth | |

| Distance between Side Frames | in |

| Length | 244 in |

| Width | 162 in |

| Height | 132 in |

| Weight | 48,000 lbs |

Accessories

NLKER SYSTEMINTRODUTION

Features:

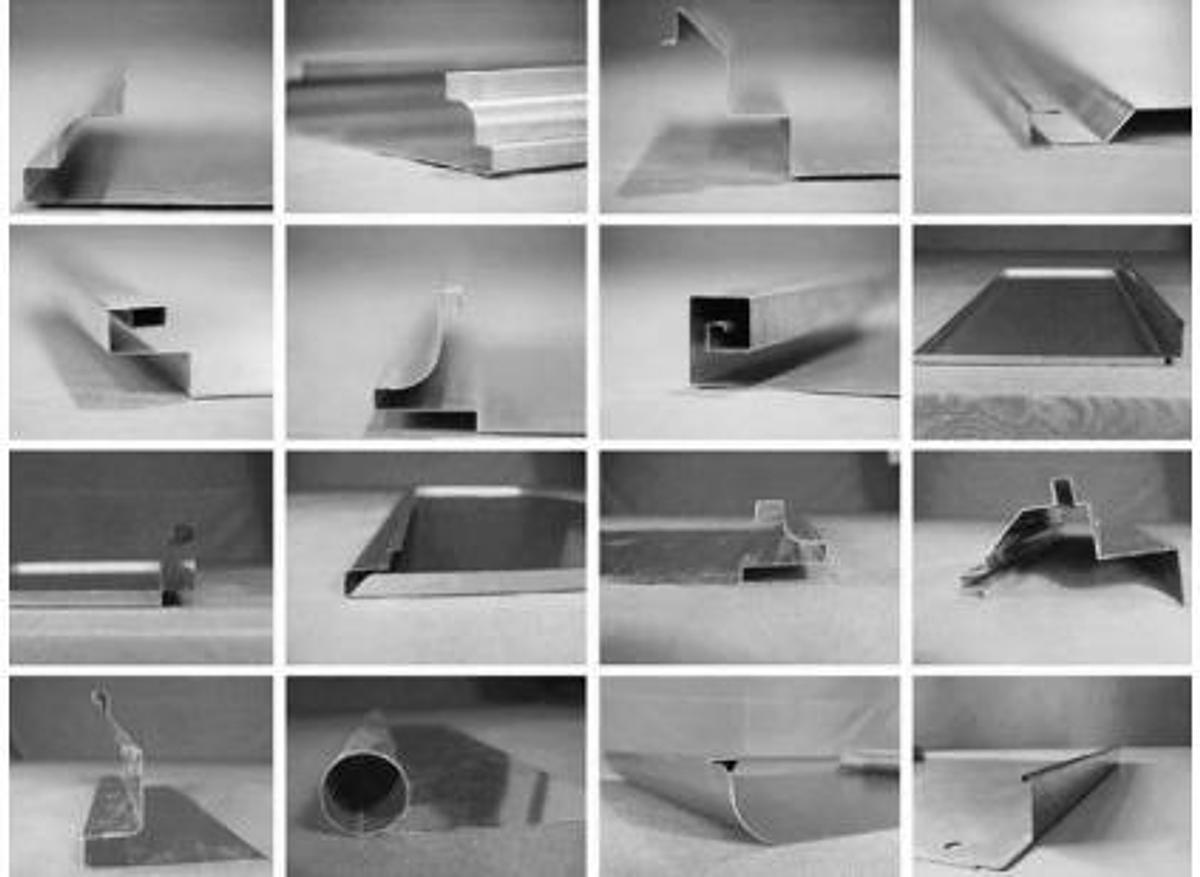

【Flexible production line】: Setting up the product programand product yield

【Bending Processing】:Bending Processing Debugging

【Program Management】: Bending Program Management

【Production Management】: Display the information of bending program processing,including processing time, the number of produced workpieces, etc.

【Cloud Operation and Maintenance Management】: Cloud server management

machine parameters, diagnostic information, etc.

【Equipment debugging】: equipment hardware parametersetting

【System management】: Software system parameter management

【Macro Program Management】:Multi-channel macro program secondarydevelopment management

OPTIONAL

Auxiliary Knife To achieve special workpiece bending

Auxiliary Knife 400 + 400mm

Segments:55+50+45+40+35+30+29+28+27+26+25+20

INSTALLATION EXPENSE

$200/day for service engineer, plus his travel, lodging and meal expense reimbursement.